I can attest that factory-made humidors are great, but they aren’t necessarily tailored to your exact requirements. You can also create your humidor. You’ll save money by making your own, and it’s not difficult to do. Furthermore, if you like woodworking, crafting things, learning about construction techniques, and safely storing cigars, you should consider making your humidor. Here is How to Build a Humidor!  You can put together an excellent humidor for your cigars without breaking a sweat if you have a little bit of extra cash (less than what would be spent on a pre-made humidor) and time. You may also personalize the look of your humidor—not just its layout—if you want to, and purchasers of standard humidors do not have this option. Let’s go through the process of making your humidor step by step.

You can put together an excellent humidor for your cigars without breaking a sweat if you have a little bit of extra cash (less than what would be spent on a pre-made humidor) and time. You may also personalize the look of your humidor—not just its layout—if you want to, and purchasers of standard humidors do not have this option. Let’s go through the process of making your humidor step by step.

Project review

- Size: 387 x 292 x 186 mm (15,2 x 11,5 x 7,3 inches)

- You can fit three trays of cigars inside

- The lid is veneered on top with a homemade veneer

Materials for DIY Humidor

| Details | Thickness | Width | Length | Material | Quantity |

|---|---|---|---|---|---|

| Box | |||||

| front/back walls | 12 | 173 | 356 | Walnut | 2 |

| end walls | 12 | 173 | 260 | Walnut | 2 |

| top/bottom panels | 12 | 248 | 343 | MDF | 2 |

| veneer | 2 | 260 | 356 | Walnut | 4 |

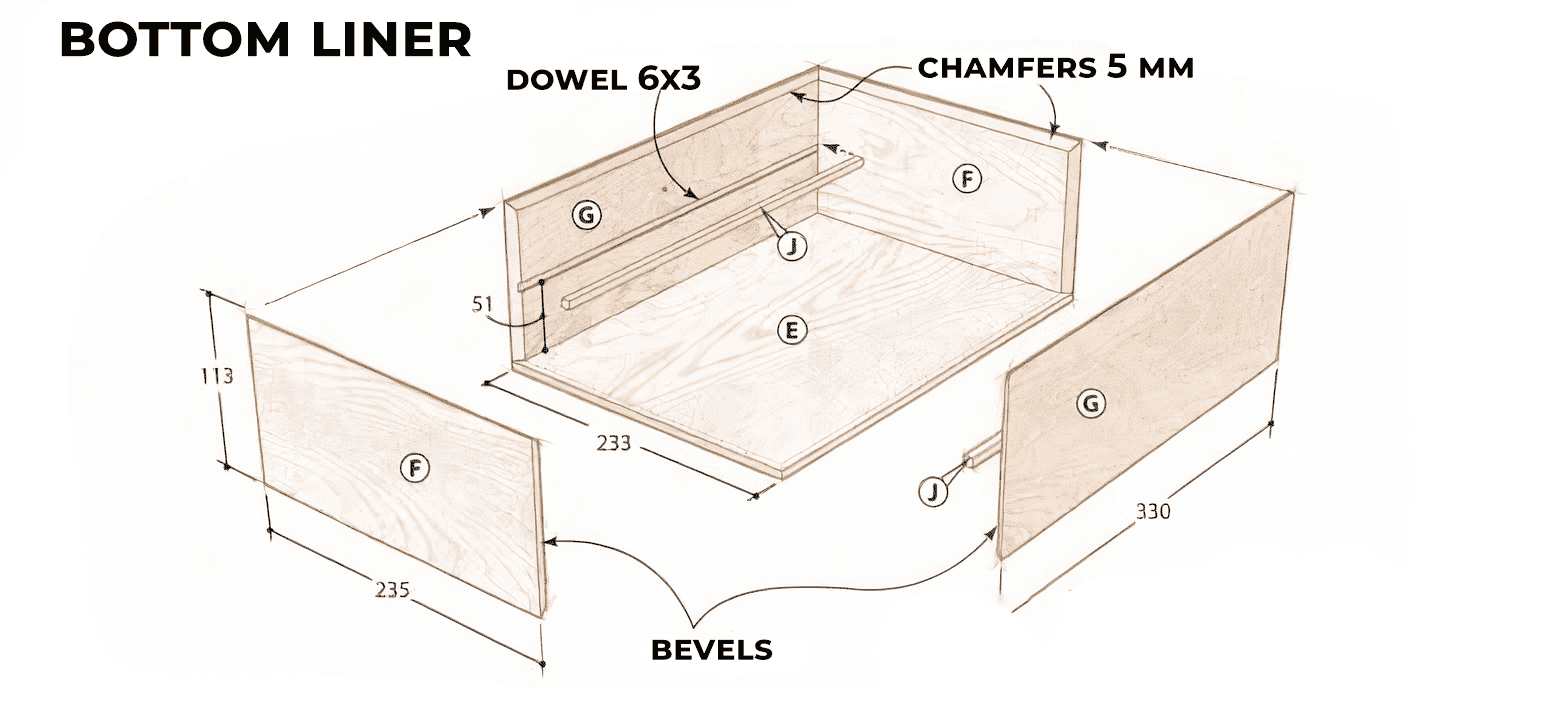

| liners | 6 | 233 | 328 | Spanish Cedar | 2 |

| bottom end plates | 6 | 113 | 235 | Spanish Cedar | 2 |

| bottom slats | 6 | 113 | 330 | Spanish Cedar | 2 |

| top slats | 6 | 20 | 330 | Spanish Cedar | 2 |

| top end plates | 6 | 20 | 235 | Spanish Cedar | 2 |

| trays | |||||

| longitudinal walls | 6 | 57 | 220 | Spanish Cedar | 2 |

| end walls | 6 | 57 | 102 | Spanish Cedar | 2 |

| bottom | 6 | 96 | 214 | Spanish Cedar | 1 |

| profile parts | |||||

| bottom longitudinal profiles | 16 | 41 | 387 | Walnut | 2 |

| bottom end profiles | 16 | 41 | 292 | Walnut | 2 |

| top longitudinal profiles | 16 | 22 | 387 | Walnut | 2 |

| bottom end profiles | 16 | 22 | 292 | Walnut | 2 |

What You’ll Need

- Access to a Table Saw

- Enough Spanish Cedar to Cover the Interior

- External Wood of Your Choice

- 12 or More Screws

- Power Drill

- Wood Stain with polyurethane

- Sandpaper

- Gloss Varnish

This list may appear to be a lot, but in actuality, it’s rather simple. To cut your wood, you’ll need access to a table saw (or a similar device), but other than that, the procedure is as simple as drilling holes and inserting screws into the wood.

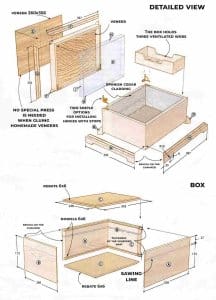

Free Humidor Detailed Plan

In this classic design, the walls are lined on the inside with thin planks of Spanish cedar to reduce permeability and maintain 70 percent humidity, ideal for storing cigars. This wood is virtually insensitive to high humidity and also has a pleasant aroma. You don’t smoke cigars? Then forget about Spanish cedar and use the humidor as a box to store jewelry and other knickknacks.

How to Build a Humidor? Step-by-step Guide

Make simple box

- Saw out the front, back, and end walls (A, B) according to the dimensions given. Measure the total thickness of the material for the lid (C) and the veneer that will be glued on top. This dimension will be the distance from the edges to the tongue and groove to be sawn on the inside of all the walls. Then saw the bevels along the ends of each wall (photo A).

- Saw the walls (A, B) lengthwise to separate the parts for the cover. Mark the flights for proper alignment during the subsequent assembly.

Tapping the stepon

- Saw the panels for the lid and bottom (C) with an allowance of 12 mm in length and width. Glue one side of each panel to the veneer (see above for a tip of the craftsman). When the glue dries, saw the panels to their final dimensions (photo B).

- Pick the folds around the perimeter of the lid and bottom panels (C) on the side not veneered to form the ridges entering the box tongue (photo 1). Glue the lid and box so that the veneer sits inside.

- We decorated the lid (A-C) with a set of homemade veneers (D), as described in the Wizard’s Tip on the next page (other set options are shown at the end of this article). After joining the pieces of veneer, trim the edges of the set, leaving an allowance of about 3 mm in length and width. Make sure that the joint lines, which are the axes of symmetry, are centered.

- Glue the veneer set (D) to the cover (A-C) as shown in photos G and H. Then trim off the excess and sand the veneer flush with the edges of the cover. Glue the veneer to the bottom of the box (C), leaving allowances on all sides.

- Milled recesses for the hinges, as described in the article “Mounting the corner hinges with a stop. It is not yet necessary to install the hinges themselves.

Humidor cladding from the inside

If you are not going to use Spanish cedar liners and make cigar trays, skip to the section “Decorating with Profiles”.

- Saw the top and bottom plates (E), which should fit into the box, and the lid with small gaps (photo I). Then saw the bevels on the longitudinal and end plates (F-I), adjusting the length of the parts to the inner dimensions of the box and cover (picture 2 and “Detailed Fork”). On the longitudinal plates (G), select the shallow bobbins. Chamfer the support rails (I), fit them to the tongue, and glue them in place.

- Make three trays so that they can slide freely into the box and rest on the battens (J). Drill holes in the bottoms (M) before gluing the trays together.

- Remove all liner parts (F-J) and chamfer the adjacent edges Set the plates and trays aside.

Decorating with Profiles

- Saw blanks for the decorative parts (N-Q) according to the given dimensions (picture “Detail view”). Mould the profile roller (photo J, K).

- To make the notches in the lower profiles (N, O), first, drill the holes, then cut to shape with a band saw, making cuts on tangent lines and leaving a small allowance. Finally, trim the edges of the cutouts with a router (photo L).

- Saw the bevels on the ends of the profile pieces, adjusted their length to the box and the lid, and glue them in place. Align the straight section of the cutout of the lower profiles with the bottom of the box.

- Tape the inside surfaces of the lid (A/B) with painter’s tape. Apply finishing coat to all parts except the Spanish Cedar liners and trays (E-M). We applied nitro lacquer three times from an aerosol can. Install the hinges and wait for the coating to dry completely.

- Fit the top liner plate (E) to the lid if required, push it into place, and secure it with the narrow plates, applying one drop of glue to the center of each piece to secure it.

- Insert the bottom insert into the box and put the trays in place, but do not hurry to put your favorite cigars in the new humidor -> check my article “How to set up and use a humidor?”

FAQ How To Build A Cigar Humidor

As a cigar smoker, why is maintaining the correct humidity level crucial in a walk-in humidor?

Maintaining the correct humidity level in a walk-in humidor is crucial for cigar smokers because improper humidification can lead to dried-out or overly moist cigars, both of which negatively affect the flavor, burn, and overall cigar smoking experience. The optimal relative humidity ensures cigars stay fresh, preserving their aroma and taste.

Can you build your own walk-in humidor as a DIY project, and what type of wood is recommended?

Yes, you can build your own walk-in humidor with fine woodworking skills. Spanish cedar is the preferred type of wood due to its ability to maintain humidity, absorb excess moisture, and add a complementary aroma to cigars. Solid wood like mahogany is also a good choice for stability and resistance to wood movement.

How important is the tight seal for a DIY walk-in or cabinet humidor, and how can one ensure it?

A tight seal is vital for any humidor, including DIY walk-in or cabinet humidors, to maintain humidity inside the humidor effectively. You can ensure a tight seal by using quality materials for the door and its frame, proper installation of sealing elements like weather stripping from a local hardware store, and regular checks for any gaps or wear.

How do Boveda packs work in maintaining humidity control inside the humidor, and how many should be used for a walk-in humidor?

Boveda packs are two-way humidity control systems that either release or absorb moisture to maintain a specific relative humidity level inside the humidor. The number required for a walk-in humidor depends on its size and the number of cigars stored. It’s best to refer to the product’s guidelines for the correct amount and placement.

For a woodworker looking to make a DIY humidor, how critical is the choice of interior lining, and why is Spanish cedar often used?

The choice of interior lining is critical when making a DIY humidor because it affects humidity and temperature stability, aroma, and pest control. Spanish cedar is often used because it helps maintain humidity, imparts a desirable scent, resists mold, and deters tobacco beetles, contributing to an ideal cigar storage environment.

What role does a hygrometer play in cigar storage, and where should it be placed inside the humidor?

A hygrometer is essential in cigar storage as it measures the level of humidity inside the humidor, ensuring it’s within the ideal range to keep your cigars fresh. It should be placed in a central location inside the humidor where it’s easily visible, away from direct contact with the humidification device to ensure accurate readings.

What are the essential steps to building a walk-in humidor for a cigar shop or a cigar aficionado with a large collection?

Building a walk-in humidor involves several steps: designing the space to accommodate the number of cigars and accessibility, selecting moisture-resistant materials like Spanish cedar for lining, installing an efficient humidification system to control humidity and temperature, ensuring a tight seal for the room, and monitoring with a reliable hygrometer and humidifier.

When making a cigar humidor box, how important is the seal and how can a DIYer ensure a good one?

The seal is crucial in making a cigar humidor box as it prevents the exchange of air from inside and outside the humidor, thus maintaining the desired level of humidity. DIYers can ensure a good seal by using quality hinges and hardware, applying weather stripping or silicone sealants, and ensuring the lid fits snugly without gaps.

Can old cigar boxes be repurposed into desktop humidors, and what modifications are needed?

Yes, old cigar boxes can be repurposed into desktop humidors. Modifications needed include adding a Spanish cedar lining to maintain humidity and absorb odors, installing a humidification device, and a hygrometer for monitoring. The box must have a close-fitting lid to maintain a consistent environment inside.

How does the humidification device work in a DIY walk-in humidor, and how do you choose the right one?

A humidification device in a DIY walk-in humidor releases moisture to maintain the desired level of humidity essential for keeping cigars fresh. Choosing the right one depends on the size of the walk-in humidor, the number of cigars, and the climate in your location. Options range from electronic humidifiers for large spaces to passive humidifiers like Boveda packs or crystal gel humidifiers for smaller areas. Always refer to manufacturer guidelines for capacity and installation.

What are the first steps to make a humidor for storing a large cigar collection, and what materials are commonly used?

The initial steps involve choosing a design from various humidor plans, selecting a size based on how many cigars you intend to store, and gathering materials. Common materials include Spanish cedar, known for its humidity control and aroma, for the interior walls and lining, and quality hardwood for the exterior.

Why is distilled water recommended for use in humidors, and how does it help maintain the proper environment for cigars?

Distilled water is free of minerals and impurities found in tap water, which can clog humidification devices and foster bacterial growth. Using distilled water helps maintain a clean environment inside of the box and ensures the longevity and effectiveness of the humidification system.

In constructing DIY humidors, what specific features must be incorporated to ensure it’s functional for cigar storage?

Key features for DIY humidors include a tight seal to keep the humidity stable, a hygrometer inside for monitoring humidity levels, and an effective humidification system. The humidor must also be lined with Spanish cedar for optimal moisture control and to impart a favorable aroma to the cigars.

How feasible is it to convert a wooden box into a desktop humidor using household tools, and what are the necessary steps?

It’s quite feasible with basic woodworking skills. Necessary steps include measuring the interior to line the inside with Spanish cedar, installing a humidification device to regulate moisture, adding a hygrometer for monitoring, and ensuring the lid closes tightly to maintain the appropriate humidity levels.

When building a walk-in cigar humidor, what considerations need to be taken into account regarding its size and capacity?

Consider the number of cigars you plan to store, as walk-in humidors are ideal for extensive collections. Ensure there’s enough room for circulation of humidified air, shelves for boxes of cigarettes and individual cigars, and space for growth if you plan to expand your collection.

Can you build your own humidor large enough to walk into, and what are the structural requirements?

Yes, you can build one, but it requires careful planning and construction. Structural requirements include insulated walls, a vapor barrier, an exterior-grade door for a tight seal, an efficient humidification system, and reliable monitoring tools like a hygrometer to ensure constant humidity levels.

How do you ensure a wooden humidor maintains the correct amount of moisture for cigar preservation?

Use a hygrometer to monitor humidity levels and a humidification device to control moisture. The interior should be made from Spanish cedar, which naturally helps regulate humidity. Regularly check the seal and the distilled water levels in your humidifier to ensure a stable environment.

What’s the importance of having the hygrometer inside your humidor, and where should it be placed for accurate readings?

A hygrometer is crucial for monitoring the environment to prevent cigars from drying out or becoming too moist. It should be placed away from the humidification device for accurate readings, ideally in the center of the space or where you can easily see it when you close the lid.

How can you modify a standard wood box to ensure it’s ready to smoke for cigars?

Line the inside with Spanish cedar, install a humidification device, and add a hygrometer. Make sure the box closes securely to maintain a consistent internal environment. Proper seasoning is also essential, using distilled water to establish the initial humidity before placing cigars inside.

For someone looking to make a humidor for a small quantity of cigars, what’s the best way to store them in a limited space?

A desktop humidor or a small wooden box can be ideal. Line the bottom of the container with Spanish cedar, ensure a tight seal when you close the lid, and use a small humidification device suitable for the space’s size. A hygrometer is also recommended to monitor conditions inside the box.